This project develops a smart shrimp feeding system to automate manual data collection, thereby enhancing the accuracy and efficiency of feeding practices.

Contributors

Lan Dang, Khoa Pham, Hung Nguyen, Bao Nguyen

Program

Bachelor of Engineering (Robotics and Mechatronics Engineering) (Honours)

Academic supervisors

Dr. Thanh Tran

Background and objectives

Shrimp farming is a vital component of global aquaculture, but traditional feeding methods, often based on fixed schedules and human observation, present significant challenges. These methods can lead to overfeeding, which causes environmental pollution and increases the risk of disease due to water quality deterioration. Underfeeding, on the other hand, hampers shrimp growth and affects overall yield. These systems aim to optimize feed usage, improve shrimp health and reduce environmental impact, ultimately enhancing both the sustainability and profitability of shrimp farming operations.

The system is a shrimp feeding system designed to provide the user with the ability to remotely turn on and off. The user could monitor the state of the system such as the amount of the feed and weight of the feed through an OLED handheld device. The system must have the capability to operate off grid for a duration in the case of power loss. And finally, the system must possess the ability to register feeding data to the cloud so that the user could read these data and perform data analysis to determine the best feeding amount and frequency for future feeding cycle.

Methodology

The machine incorporates a centrifugal feeding system that could disperse the shrimp feed in a 360-degrees fashion. The rate and range of feed is controlled through the means of varying the rotational speed of the feeding blade. This rotational speed could be controlled using an RF remote controller, and the same controller could be used to turn the machine on and off. An array of sensors on board the machine returns data to the user regarding the weight and amount of the feed left in the tank. An internet chip on the machine also uploads the data directly to the cloud database, so this data could be later analysed. In the situation of power loss, the machine could be powered by a series of 12V battery that get continuously charged from the solar panels equipped with the machine.

For feeding optimization, the user could infer from the past data to determine the best feeding amount and frequency for future feeding cycle. This could be done by interacting with the web application. The application pulls data from the cloud database to perform data analysis tasks like data visualization and provide simple mathematical functions so that the user could inquire deeper insight on the graphs and charts at display.

Experiments and resutls

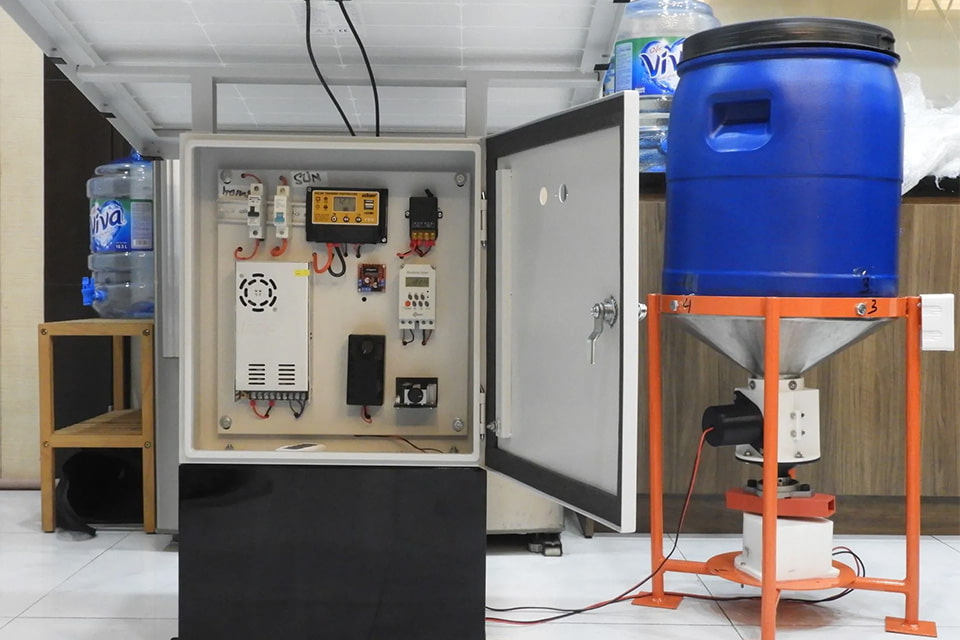

The prototype feeder setup includes a control panel with electronic components inside an open cabinet, connected to a blue feed hopper with a red stand.

The prototype feeder setup includes a control panel with electronic components inside an open cabinet, connected to a blue feed hopper with a red stand.

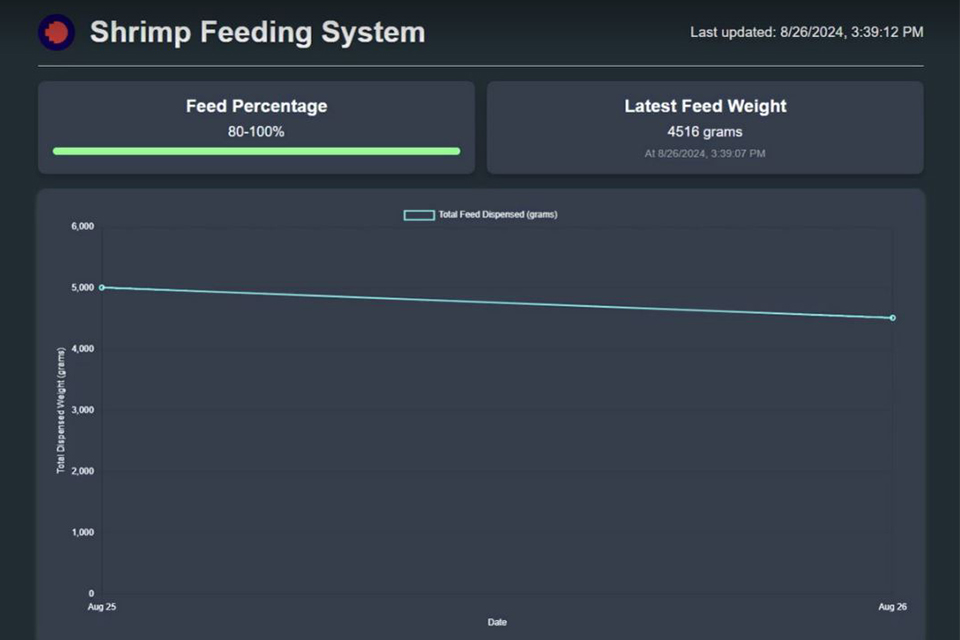

The web interface of the shrimp feeding system displays current feed percentage at 80-100% and latest feed weight of 4516 grams, with a graph tracking total feed dispensed over time.

The web interface of the shrimp feeding system displays current feed percentage at 80-100% and latest feed weight of 4516 grams, with a graph tracking total feed dispensed over time.

Through experiment and testing, it has been shown that the features match their determined capabilities. The LoRa module is able to transmit data in the range up to 5km. The solar panels and batteries could power the system for up to 10 minutes in the case of power loss. In addition, the web application successfully retrieved data from the cloud database to perform data analysis.

Conclusion and findings

Our project centers on an advanced automatic shrimp feeding system, emphasizing its robust mechanical features designed for efficient and precise feed distribution. The system can dispense feed automatically based on preset schedules and quantities, or manual adjustments via a control panel or remote control. The feed tank has a 35kg capacity. During each dispensing cycle, it releases about 5 kilograms of feed within 1 minute and 40 seconds, covering a radius of up to 10-15 meters of the shrimp’s pond. The mechanical design ensures consistent and precise feed delivery, which is crucial for maintaining optimal feeding conditions. Additionally, the system is integrated of sensors and IoT technology which supports real-time monitoring of the feed percentage, the latest feed weight dispensed and the chart displays the total feed amount dispensed daily over a week. Additionally, the system includes a LoRa-based offline device that allows users to observe the feed percentage within a 3km radius, even without Wi-Fi connectivity. This project prioritizes the mechanical efficiency of feed dispensing, ensuring reliability and precision, essential for maximizing shrimp growth and minimizing waste, moreover, providing flexible monitoring options for farmers.

This project shows the feasibility of incorporating existing IoT technology with automatic farming equipment into something that has the potential to benefit the farmers greatly. Though this prototype is constructed using only development boards and 3D printing material, it demonstrates the potential of scalability. If optimized for production, this machine could change shrimp farming for the better.